Writing that last blog post making the astounding claim that the boat was about done? Ha! Boats are never done! I’ll be working on something on this boat the day before we sell it. As I said in an earlier post, we get one thing done and then decide to do something else we hadn’t even noticed that we wanted to do. Last week it was replacing the steps on the ladder going topside. They were starboard plastic, three inches wide, and perfectly serviceable but hard on bare feet. Now they are five inches wide and made of tigerwood, a type of teak.

I found the tigerwood at Jefferies Supply, a neat place over towards the mountains:

Off the path, for sure, past a cemetery, down a narrow beat-up road and hidden in a whole bunch of empty and abandoned warehouses is this lumber supply place. Nice guys, helped me find what I needed, and they carry just about every kind of wood known to man. They had two pieces of tigerwood just the right width at a reasonable price.

While doing this project I used my dad’s old router, a tool I remember dad (and me) using when I was in high school. Through some aberrant dysfunction in the space time continuum that I have just now noticed, that was over 50 years ago. So this tool is half a century old, and I’m still using it, and thinking about my dad while I do. Made for a pleasant day’s work.

Before, skinny and hard on the feet:

After: Cheryl is smiling, so I know I did good.

We also added straps, cables and some tubing to the bimini top to make it more stable and less likely to fly off in the wind. A flood light under the arch with a switch inside for night maneuvers with the dingy, or just to light up the back of the boat in case we get boarded by pirates at night.

I spent quite a while removing old wires and hoses and dead bilge pumps, I keep finding that kind of thing. Remember the old “spontaneous generation” theory of life rising from non-living matter, when people used to believe that mice sprung up from old rags? Thank goodness Louis Pasteur came along and straightened that out, but then, he never worked on a boat. I’m not so sure that old boats, late at night while we sleep, don’t just create wires that go nowhere and dried up old hoses that are connected to nothing. Of course cleaning that up means I keep seeing things to do. I used some of the existing but unused wiring to add a large bilge pump to the very rear of the bilge, neatened up a lot of wiring as I did that, discovered no one had wired up the start batteries to the three-bank battery charger so I did that, then noticed that the installer had also neglected to add a bonding (ground) wire to the charger, so I did that. Also added a small LED indicator light near the icemaker so we can tell when the inverter that powers that is on and the same with the solar. All typical of the kinds of endless projects a boat conjures into being.

We’ve also taken time to have some fun. One day we had a great lunch visit with Tim and Beth, two future Loopers who are about a year away from heading out, and who were gracious enough to give us a 150 feet of poly rope they had extra. One weekend we took the boat downriver a few miles for an overnighter, to get away and to try out all these systems that I’ve worked on.

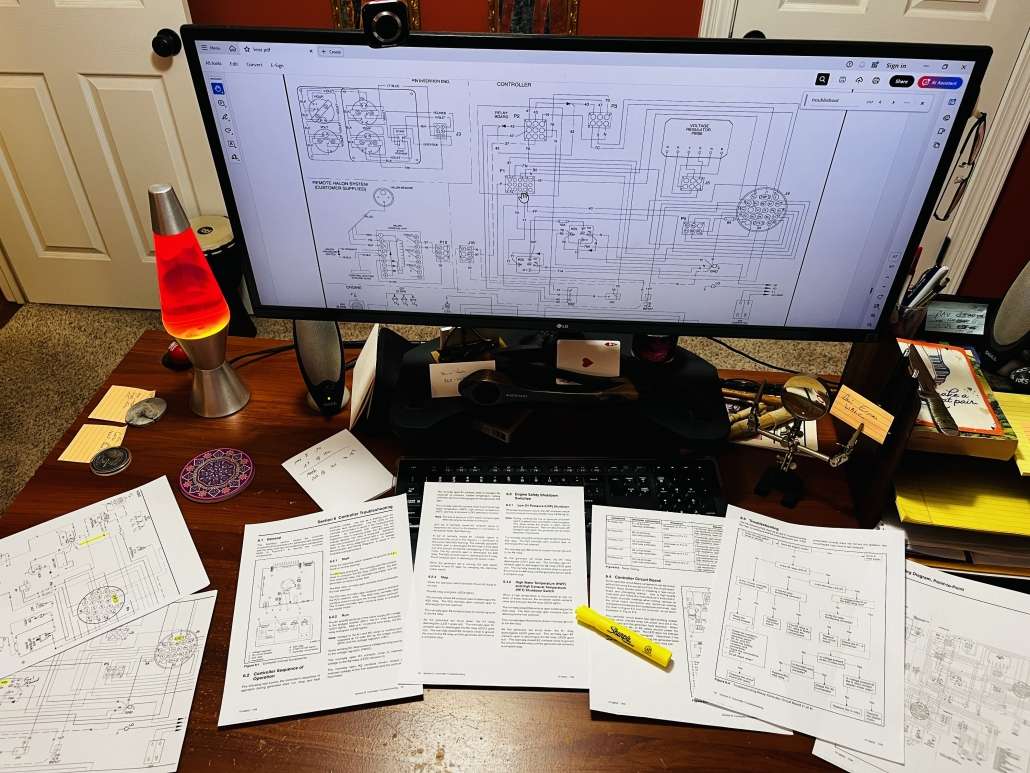

Unfortunately, a few days previous, we were running the generator and it spit out a puff of smoke and died. Uh-oh. Not a good thing. So I got online and found the wiring diagram, blew up some sections and printed them so I could highlight the wires I needed to follow, then went down to the boat and started taking things apart. As always, finding the problem is far more time-consuming than just fixing it. I went back and forth from the generator to the wiring diagrams and the troubleshooting steps until I figured out which wires should have power and found two that did not, so I went backwards testing things as I went. I could find no melted wires, no burnt circuit boards, nothing. A mystery that was kicking my butt for a while.

This is what I am dealing with. Somewhere in there is a problem.

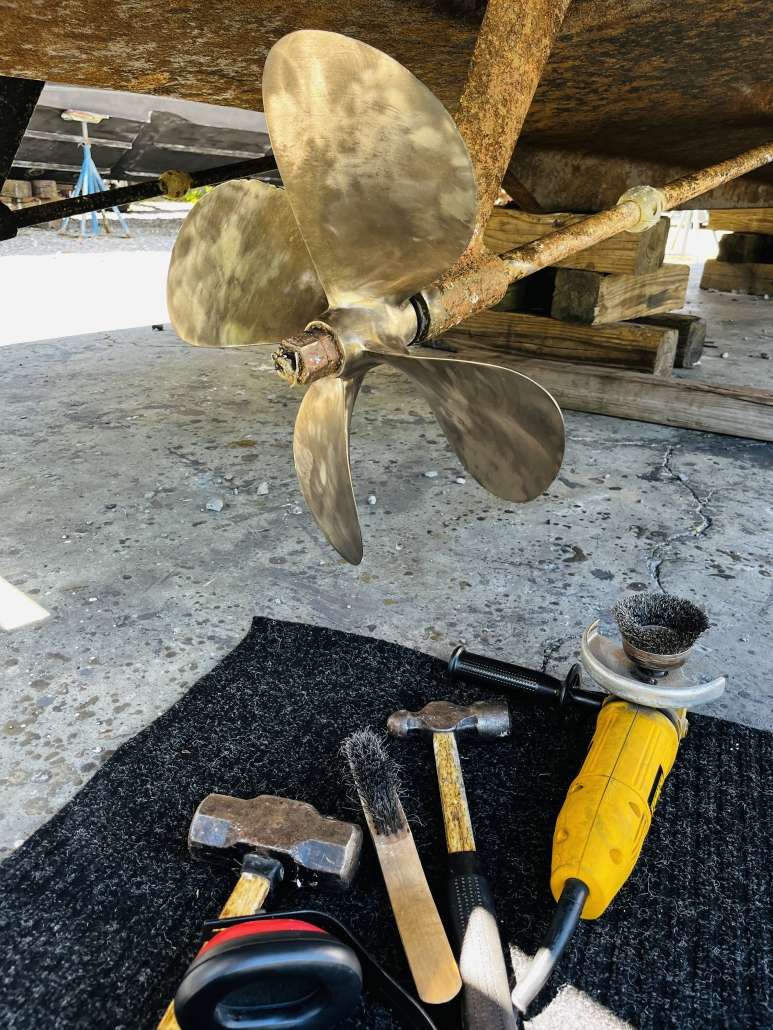

Finally while tracing down a wire I found a connector with two wires that had overheated and fried. Corrosion, I’m guessing, when we get the boat home I’ll replace those and see if that does the trick. As of this writing, the boat is on the hard, getting some minor work done and so I could inspect various things underwater. All looks good, although the props needed a good cleaning and polishing. (Thanks to our friend Max who helped us get the boat down to the boatyard.)

I think I’ve mentioned this before, but figuring out some of these problems and solving them is just kinda fun. For instance, there is an electronic box in the engine room that diverts the power from the alternator to the batteries, in effect it splits that power so that both banks of batteries get charged. It’s an old diode box, basically, the same vintage as the boat. Remember what electronics were like 26 years ago? Well it had died, one side no longer worked. There are new ones out now, using new technology, more efficient and all that, also more expensive. And of course this one is no longer even made. However, we’ve got Ebay. I found a new old-stock one, 26 years sitting on a shelf, still in the beat-up packaging, at a great price. Problem solved.

Another of the projects I hadn’t even considered until I was down working on the engines was to add gas struts to the engine room covers . This was our solution:

This week, after lunch with Will and Jackie, who are also working on their boat with plans to head south in November, we ran the boat back to our slip, and the forecast for the trip was for maybe some sprinkles. Well it wasn’t quite a biblical downpour but it sure wasn’t just sprinkles either. Cheryl seemed to think I needed to see, but hey, as long as I could see the front of the boat, I was good to go.

And in the midst of all that activity, we took off a couple of days to camp at Elkmont, where the green is the greenest green you’ll ever see. I spent most of my time in a chair, reading. You can observe Cheryl in the wild, occupied with her favorite camping past time.

Camping really does reset your priorities. Camping is for the mind what a high-speed run on the highway used to be for a car. It tends to blow out all the sludge that accumulates thanks to the type of urban life most of us are forced to put up with. A few days with no phones and no internet and no traffic while reading for hours and looking around at raw nature allows your brain to cleanse itself or reboot, I’m not sure which, but it sure is nice.

With any luck the next time I’m on here I’ll be able to report that the generator is fixed, and that we’ve had the boat out several times. That is the goal for the next few weeks, in between trips and visitors and a whole bunch of other fun stuff we have going on that I already can’t wait to tell you about.

“Languor is underrated. It is not possible to be immobile in modern urban society except by dint of constant effort. Holding on tightly to the riverbank and fighting the current is not languor. Nobody likes that. But bone-lazy idleness, hours and hours spent staring at the sky and remembering books and birthdays and great kisses; this is pure pleasure that eludes the productive in all their confident superiority.“

great update! yes, you are never really ‘caught up’. but sure looks like very enjoyable projects. the steps and cover lifts are perfect! please keep the blog active

The top step is one of my favorite things about the entire boat! Come check it out…

I am slowly catching up on your blog posts. When we purchased CASPIAN, we started one called CASPIAN’s journey. It was about the journey the boat was on from the point of almost unusable to the comfortable cruiser is now. I agree, a lot of the fun is figuring out innovative solutions to problems and putting them in place. I bask in all of the projects I’ve done every time aboard. Speaking of projects. I see that the engine bay covers on your boat consist of three parts, on CASPIAN there are two and that is very inconvenient. Anytime I need to get down there for a few moments I either lift the port side and have to slide past the port engine on the heat exchanger down into the middle of bilge, or I have to move the table to open the starboard side that covers the middle of the bilge. The three-cover design allows easy access through that middle hatch. If I was keeping CASPIAN that would surely be one of my next projects and it would turn into a recarpeting project.